The Legend of Riley Hopkins: 50 Years of Innovation, Grit, and Screen Printing | Let's Talk Shop

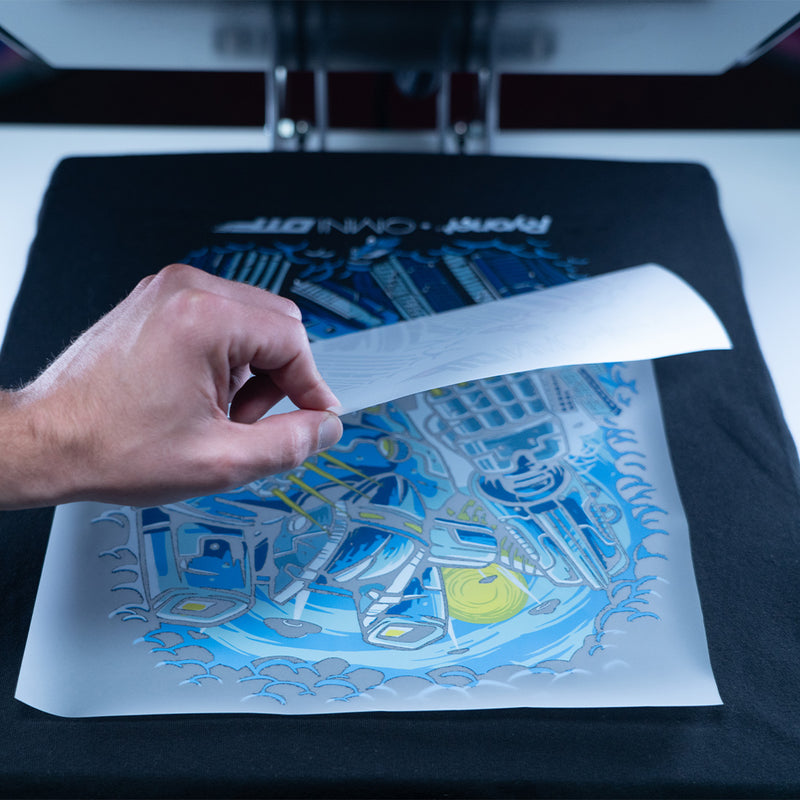

If you’ve ever pulled a squeegee or loaded a shirt onto a manual press, chances are you’ve felt the legacy of Riley Hopkins. His name is etched into thousands of...