Okay, so you’ve heard their names — CMYK, Spot Color, and Simulated Process — but what are they? What sets them apart from one another? What is the best use for each technique? Let’s go through them, one by one.

CMYK PROCESS (CYAN, MAGENTA, YELLOW, BLACK)

WHAT IS IT?

CMYK is the oldest color reproduction print method. Screen printers. can print designs on white or light-colored garments using cyan, magenta, and yellow. For users skilled in CMYK file preparation, Photoshop, and screen creation, this is still a viable print process for light-colored garments. CMYK is implemented less because simulated printing is more dominant.

PROS:

- Can be printed with plastisol or water-based inks

- Soft hand feel

- Meant to be printed wet on wet

CONS:

- Need to be knowledgeable on how to properly separate colors in the correct software programs.

- Limited garment color selection (white or light-colored garments).

- Requires a deeper understanding of mesh selection and reproduction of halftone values.

- Limited color spectrum — printers will not be able to reproduce certain colors. If a printer needs a vibrant red, they'll need a bump screen to print that color.

SUGGESTED TOOLS:

- Use Photoshop to separate colors. Do not use a vector program to separate.

- Rip software for the film output.

- The Color Profile for inks you're using.

SPOT COLOR

WHAT IS IT?

Spot color is the most common print technique in the industry, and has sometimes been called the screen printer's best friend. Knowledge of creating, applying and handling spot colors is essential to any screen printer. Logos, text, cartoons, line art, and more are all styles spot colors excel at reproducing. Spot color designs are usually created through the use of vector graphics programs such as Adobe Illustrator. There are many programs that can create spot colors. Spot colors (such as Pantone or custom mixed) can be printed as solid shapes at 100% tint or halftones by changing their tint value away from 100%.

RELATED: WHY PRINTERS NEED TO MASTER ADOBE ILLUSTRATOR FOR SCREEN PRINTING

PROS:

- Vivid color values

- Excellent user color control

- Clean edges

CONS:

- Traditionally limited to solid color with some halftones and vector illustrations. Spot color does not reproduce every kind of print; for example, it doesn't work for photographic designs.

- Manual user file preparation (under-basing, choking, spreading).

SUGGESTED TOOLS:

- RIP software

- Vector graphic programs like Illustrator

SIMULATED PROCESS

WHAT IS IT?

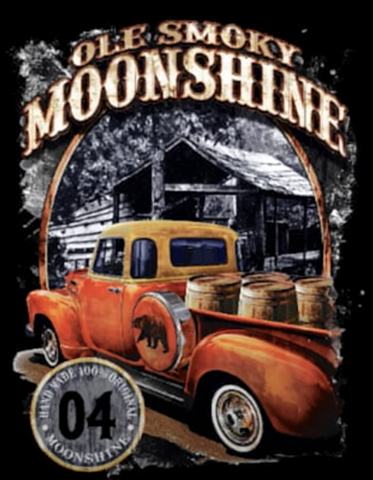

Simulated Process is a method used to reproduce almost any image on the market. It does so by overlapping and blending colors in a method similar to CMYK through using halftones and spot colors and/or PMS colors. Essentially, it's a way of taking an image that historically would have been printed via CMYK, but instead uses more opaque ink to create a more stable color and production friendly ink that can print almost any design for any garment. Designs that are too difficult to separate in a vector program, raster images, photographs, complex tonal illustrations — all doable with Simulated Process.

Since the 90’s, Simulated Process has become more prominent and widely accepted because it's easier to separate, print, and achieve the best, completed garment compared to CMYK. Simulated Process is more stable during production, resulting less misprints. It's the preferred separation printing method.

With any new technique, a printer should thoroughly research the method and practice before implementing in their shop. Look online for information. Facebook groups like Rogue Printers is a great place to ask experienced printers for help. YouTube is another great platform to learn more about the process. If you do not have the bandwidth to learn more about separations, freelancers that specialize in separations can help you.

PROS:

- High-end, high-detailed artwork and graphics.

- Detail capture maintains immense level of details (resolution of image and LPI).

- Flexibility: Print on any color of garment due to a white base.

- Fast printing times with potential flashing across all garment types, which you cannot do for CMYK printing.

- Vivid expanded color values due to using specific spot colors to achieve expanded tonal spectrum.

- Greatly expands the user's ability to service client needs.

- Works with water-based inks, PVC free inks, discharge, plastisol inks, and discharge underlay technique.

- Soft hand

CONS:

- While the barrier to entry is low, printers do need to educate themselves by finding information online or connecting with screen printing experts and practice the technique.

- It's not ideal for reproducing fine text or sharp, vector-like edges.

SUGGESTED TOOLS:

- Photoshop or other program

- RIP software and Film Output Printers

- Dedicated ink kit for software system, PMS mixing system, or close colors

- Higher mesh count screens with high uniform tension

Now you know the difference between CMYK, Spot Colors, and Simulated Process. Each style of printing has its benefits and drawbacks. It’s all about what works for your shop. Try out methods you’re curious about and find the best process for you.