No matter what size your screen printing operation is or what market it caters to, the goal is to get jobs through the shop and out the door on time — whether that means a two-week turn or a matter of hours. Screen printing businesses differ in terms of focus, equipment, staffing, capabilities, etc. But one thing successful ones have in common is an organized workflow. Let’s look at the various steps in the printing process and how they impact each other in your shop’s workflow.

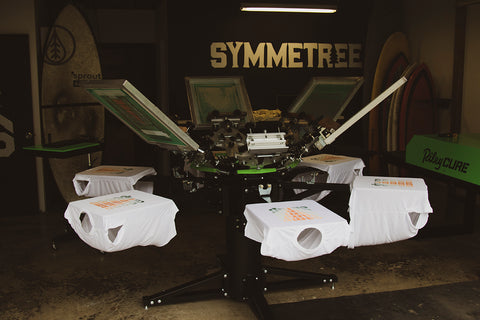

Photo by Symmetree Clothing

CAPTURE ALL THE INFO

An organized workflow allows for effective production scheduling. It all begins with the placement of the order. Documenting jobs as they progress from initial consultations through estimates to actual orders provides the information you need for successful scheduling. It’s critical to always get the style, size and quantity of garments required.

You want to make the process as foolproof as possible so you don’t impact scheduling. Keep track of all the variables involved. These variables include both the numbers and design side of the job, and they need to be tied together.

For instance, you have to keep on top of the total number and type of garments in the order, as well as any subsets within it, such as color, design or placement changes for certain quantities, sizes or styles. Where there are deviations, split the order into segments, like “1A,” “1B” and “1C,’ with corresponding art proofs attached.

The system you use can be as simple as file folders and Excel sheets or as sophisticated as commercial or custom shop management software. What’s important is that you capture the job specifics and have them organized in a way that makes it easy to access the information required at each stage of production. The size of your team will dictate how much data needs to be dialed in, as well the best method for ensuring it happens.

What you’re aiming for is to set up the process for success at each stage. When the order specs are finalized and it goes to the production floor, the screen maker should know exactly what is required of them. Then, he should be able to easily pass off applicable information to the screen printer, and so on. Each production area should also have its own system or organization as well.

Pro Tip: Staying organized is key to staying on track. Even if you’re the only printer in the shop, keeping diligent notes about every job will take the guesswork out of your production process. Then, if you ever need to repeat the job, you’ll have all the info all ready to go.

RELATED: A TIP ON MANAGING CUSTOMER EXPECTATIONS

SET UP A SYSTEM

One approach to organizing your job notes is to keep area-specific forms in manila folders that are labeled alphabetically. Imagine you have a manila folder specifically for your darkroom.This way, you can analyze art proofs, make sure the jobs line up, and more without carrying the entire job packet with you to your darkroom. After the screens are exposed, the garments can be divided according to the jobs and sub jobs on your estimates.

Similarly, the job packet supports correct screen setup and helps in achieving exact reproductions of art proofs on test prints and beyond. This carries through into production, where it contributes to quality control by helping to ensure consistency and provides the basis for accurate counts. Make sure to take notes throughout the process about what worked and what didn’t. When in doubt, write it down.

Photo by Golden Press Studio

STICK TO A SCHEDULE

When it comes to actually scheduling production, there are a lot of variables to take into account. Number 1, of course, is meeting the deadline. You also have to factor in the other jobs already in-house or in the pipeline, including their size, type and complexity. On top of that, you may have to consider availability of equipment and personnel. The top factor to keep in mind? The customer.

Have you ever planned out a job that got held up? A number of factors can put a job on pause, randing from problems with art approvals and equipment malfunctions to late/incorrect garment shipments. Make sure you bake in some extra time for unforeseen changes so your production schedule doesn’t fall apart.

SCHEDULING FOR SUCCESS

Depending on the size of your operation, scheduling may be done manually or using a computer, either communicating the information to the production team or sharing it online. The responsibility may fall on the shop owner or office manager or in larger operations by the general manager or production manager. No matter how it’s done or who does it, certain elements are key to successful scheduling. Here’s a few:

Transparency. Whether the schedule is written on an easily visible whiteboard/chalkboard or created in the cloud so it can be viewed from cell phones and other devices, it has to be readily accessible. It’s essential that everyone knows what he or she needs to do today and tomorrow and be aware of what’s on tap for at least the coming week. This is especially important for the screen department, which needs to be burning jobs ahead of time.

Flexibility. Scheduling has to allow for changes. New orders come in everyday, including rush orders, and they may require a machine that’s been booked for another job. You may come up 10 shirts short. A schedule is a living thing, and it is critical to keep it updated. Whether this is easier to do on a board or a computer depends on your situation. What’s important is that it’s in writing and current in real time.

Understanding the job. Taking time to evaluate the requirements of jobs as they come in lets you identify those with similar requirements in certain areas and factor that into your scheduling for time savings. For example, you may want to run jobs calling for the same colors back to back or schedule orders on the same types of materials one after another to minimize downtime for re-tacking, changing or cleaning platens.

Photo by Salt & Pine Co.

Understanding the customer and your business. While it’s not ideal to push a deadline, it’s not as critical an issue with some customers as with others. If the customer isn’t stressing and you have a solid relationship, sometimes making a call can alleviate your stress over scheduling. If there isn’t any flexibility, you may get into overtime. Hopefully, you’ve built in some sort of margin to offset such situations, but if you find them occurring frequently, it may be time to explore what it will take to improve your printing capacity.

It’s also important to take your overall business strategy and how you’re positioning your company in the market into account. Two weeks traditionally has been the standard turn time in custom apparel printing. However, with online printing operations touting faster turnarounds, some conventional shops with the capability are focusing on quick turns as a business niche. This can be a competitive edge if you can figure out how to do it, and a large part of that comes back to scheduling.

RELATED: TOP 3 CUSTOMER SCREEN PRINTING COMPLAINTS AND HOW TO HANDLE THEM

Knowing your friends. In any aspect of printing, it helps to have a network you can tap to help you out if you run out of ink or need to farm out a job that just won’t fit in your schedule. This isn’t always possible, but developing a relationship with another printer you respect and trust can each scheduling headaches all around.

UPGRADE YOUR EQUIPMENT

Having the latest and greatest isn’t always best for your shop. But when you’re unable to keep up with your schedule because of a shortcoming in your production process, it might be time for an upgrade. Find your pinch points and upgrade when necessary. Here are some common equipment upgrades printers find helpful.

EXPOSURE UNIT

LED bulbs are the new standard. Their spectrum of light output and wattage speeds up the screen-making process and improves the quality of the stencil. Expose screens faster with far less energy. Capture more details and maintain better image resolution. Strengthen a screen’s durability. LED exposure units enhance darkroom processes, production, and the quality of the print.

You don’t have to break the budget to upgrade to an LED unit. By purchasing a compression unit, you can expose an insane amount of detail and still save some cash.

Photo by Aerogant Printing Company

SCREEN PRINTING PRESS

Every screen printer’s journey starts a little bit differently. Some go all-in with an 8 color, 6 station press, while others prefer to learn on a smaller press and upgrade as their shop grows. If you’re printing on a 1-station press, you may notice that jobs take longer to print, and you may be restricted to shorter jobs.

By upgrading to a press with more platens, you’ll be able to print jobs more quickly. With an extra platen or two, you’ll be able to flash and print at the same time. Another perk of upgrading to a bigger press is the advantage of more color stations. The more color arms you have, the bigger jobs you can print. Or, if you have a bunch of one-color jobs, you can set them all up on the press and keep the hustle going.

RELATED: BUYING YOUR FIRST MANUAL PRESS? HERE’S 5 FACTORS YOU SHOULD CONSIDER

Photo by Symmetree Clothing

DRYING CABINET

Let’s be honest: drying screens takes a long time. If your darkroom isn’t dialed in, you may have to wait hours for your screens to dry. How can you improve this? Buy or build a drying cabinet.

A dry box doesn’t have to be a box. If you’re in a home shop, a closet is a great idea. It’s already separate from the rest of the shop. A closet is usually dark already, and since it’s meant for storing things, it’s perfect!

To create the perfect environment, you’ll need a dehumidifier, fans that blow directly across the screens, and warmth. In a self-contained box or small space, the heat coming from the dehumidifier is all you’ll need. Use a hygrometer to check temp and humidity levels in the dry box. Your humidity should always be under 40% in the box.

A drying cabinet or box will keep your screens dust-free and will dry your screens much faster than simply letting your screens air dry.

RELATED: EVERYTHING YOU NEED TO KNOW ABOUT BUILDING YOUR OWN DIY DRY BOX

CONVEYOR DRYER

Curing garments with a flash unit, heat press, or heat gun may get the job done, but when you have big orders coming in, using these curing methods may take too long. Your best bet? Upgrade to a conveyor dryer. Conveyor dryers run multiple shirts through at a time, which helps speed up production. When looking at conveyor dryers, you have a ton of options.

Printing water-based ink? You’ll want a forced air conveyor like the Aeolus. Water-based inks need air movement to effectively drive the water out of the ink and move the steam outside the dryer so that the heat can cure the ink. Without proper air movement, most printers either have to slow their belts way down or run the shirts through the dryer multiple times. Plastisol inks can be cured with any standard conveyor dryer.

RELATED: SUPPLY AND EQUIPMENT UPGRADES THAT IMPROVE PRODUCTION AND QUALITY OF PRODUCT

Photo by Golden Press Studio

Keeping all these factors in mind when scheduling a job can be a daunting task. Find a system that works for you, and keep making small improvements when you see them. Whether you’re upgrading to Printavo or upgrading to a press with more platens, make sure that the improvements you make will set your shop up for even more success.