Screen Coating Made Simple with the Grunig G-Coat 406S

You know that precision is essential, especially when it comes to coating screens. The latest innovation to land at Ryonet is designed to take the stress out of that critical...

You know that precision is essential, especially when it comes to coating screens. The latest innovation to land at Ryonet is designed to take the stress out of that critical...

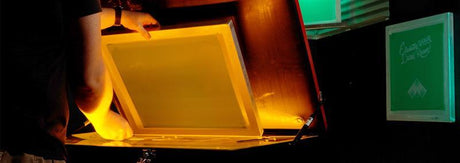

Welcome back to another Deep Dive with Colin! This topic will be focused on a fundamental aspect of screen printing: coating a screen to get a perfect stencil. This is...

To create a stellar print, you need a solid screen. Using high-quality emulsion and dialing in exposure times help, but it's a fraction of what's needed. Your darkroom matters. One major update...

Every screen print starts in the darkroom, and every screen starts with a good coat of emulsion. Follow along as darkroom expert Colin Huggins walks through the basics of mixing...

Coating a screen is important to create the perfect base layer for a great print. Accomplishing this task can be done in a couple of different ways. You can coat screens by...

Many printers exclusively use plastisol ink. If this sounds like you, check out Baselayr Plastisol emulsion. The high performance emulsion will streamline production by exposing faster, rinsing out quicker, and reclaiming...

Advanced screen printers. High production print shops. We’re talking to you. If you’re pushing the limits of your emulsion, check out Baselayr Complete. Wondering how it'll work in your screen...

If you’re part of a larger shop, or even if you’re still getting there, then the idea of coating 400-500 screens in an 8-hourt shift at a 2/1 coat must...