A Checklist of Equipment & Supplies Needed to Start Screen Print Shop

Ready to start screen printing? It's a big jump, but it's so worth it. To build your shop, you will need to obtain some equipment and supplies. Our Sales and...

Ready to start screen printing? It's a big jump, but it's so worth it. To build your shop, you will need to obtain some equipment and supplies. Our Sales and...

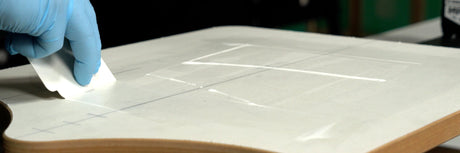

Sgreen® Stuff, a dynamic dual-action dehazer and degreaser, is your secret weapon against ink haze, oils, and contaminants. It's your key to ensuring that your emulsion adheres perfectly to the screen. Let's...

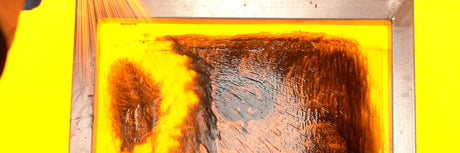

Efficient reclaim is important. The goal when reclaiming screens is to accomplish as much as possible in as little time as possible, so you can get back to printing. It’s...

Reclaiming isn’t the most fun part of the screen printing process. With all the scrubbing, waiting, rinsing, and scrubbing some more, it can become a tiresome task. It doesn’t have...

Keeping a shop clean is essential. A clean shop not only keeps the space looking nice but keeps your equipment running at max capacity. If you’ve used aerosol adhesive, you’ll...

A screen printing job takes a lot of man hours. The whole process, from art prep to screen reclaim, takes time and effort to constantly hone in processes and learn...

If you have ever had to pay for a drain cleaning service or plumber to come to your shop to unclog your drain, you already know why you should be...

Washing and reclaiming screens is important. For small shops where space is limited, this task can get tricky. Printers have to get creative when washing out their screens. Here’s a...

Reclaiming screens has to be one of the most tedious parts of screen printing. Who hasn’t procrastinated and left screens sitting by the washout booth without reclaiming them? With the...

It’s no secret that some screen printing chemicals are hazardous to your health. Safer alternatives are out there. If you’re looking for chemicals that are kind to your body and...

Screen cleanup: satisfying when done right, frustrating when hiccups happen. It’s a simple process, but there are nuances to properly cleaning your screens that will keep them cleaner and make...

The screen printing process creates waste, particularly in the form of inks, emulsions, and the chemicals used to clean them off screens and tools. Some of this waste is hazardous....

One of Ryonet's values is to serve. To serve the printer, whether they need guidance for picking their first press or need help figuring out why their garment isn't curing properly....