You pull a squeegee across a screen, and it doesn’t lift off the shirt. You sigh. Another screen to replace. What if there was a solution? Well, get excited. There are different types of screens to help printers improve print performance. Besides static frames, click frames and re-tensionable frames exist. They’re not for every shop but can improve performance. So what’s the difference? We’ll compare static and click frames to see which screen benefits your shop.

STATIC FRAMES

Static aluminum frames are most common in the screen printing industry. To create static frames, the mesh is glued to the frame with a compound that’s essentially super glue. The screen is engineered to last as long as possible while still being durable enough to withstand shipping.

For most printers, static screens are a great option. With tons of mesh count options — from 24 to 355 mesh count — there’s a screen for every type of job, whether that’s glitter ink or water-based CMYK. Static screens are also economically priced. One 20”X24” screen is approximately $25-$35. Printers can also buy screens in packs to build up stock of their most common mesh counts or purchase an arsenal of 20 screens to fill out their inventory. All you need to do is purchase the screen, wait for it to arrive at your shop, and degrease it. It’s ready to go without any extra effort.

But there’s one main issue with static frames. Once these screens lose tension, the entire screen must go. While re-stretching static screens is possible, it’s often expensive and easier to simply buy new screens. Depending on how many screens a shop is going through, replenishing its stock might be more wasteful than helpful.

The Baselayr Premium Frame takes static screens to the next level with its durable aluminum construction and specialized red glue that locks mesh in place. While some static frames can lose tension over time, these frames are engineered to maintain high tension longer, delivering sharper prints for extended use.

As a rule of thumb, 25 newtons of tension is considered “good” tension. Not all mesh counts can achieve this on a static frame. The lower the mesh count of a screen, the harder it is to maintain high tension.

Since static frames aren’t stretched fresh before shipping to customers, they can lose tension while sitting on the shelf. Think of it like a donut: you want the freshest donut in the case, not the one that’s a couple of days old. It’s still edible, but not as tasty as the donut that was baked fresh.

Static frames ship as one unit, with the mesh already glued to the frame. High-tension screens are prone to break during shipping if they are at high tensions, so the tension of static screens tends to be a bit lower.

CLICK FRAMES

Click frames, like Eco Frames, have four locking strips on each side of the screen. The mesh clicks into place using these locking strips. Let’s be clear about one thing: click frames are not re-tensionable screens. However, click frames usually have higher mesh tension when compared to static frames, and offer printers more flexibility.

When you order click frames, the mesh ships in a pack, and the frame ships without any mesh. This is helpful because the mesh won’t need to survive shipping. It can be applied fresh in your shop. Simply click the mesh into the locking strips and lock it in (the mesh is held in place through tension). Apply tape over the strips to protect the mesh, and let it rest for about 24 hours.

Eco Frames come with a higher setup cost than static frames but quickly earn their keep. A starter kit comes at around $439, including six frames and 12 mesh panels. If you were buying static frames, you could buy about 15 screens at that cost. But before you get sticker shock, let’s talk about the return on investment of click frames.

When a click frame screen loses tension, all you’ll need to do is replace the mesh. Mesh for Eco Frames comes in a variety of mesh counts, as well as Hi-DRO (thin thread) or Hi-TEX (standard thread) options. Instead of being limited to just the screens you have on hand, and finding storage space for all of them when not in use, you now have access to every mesh count available in a convenient collapsible panel. A six-pack of mesh costs approximately $99, while six static screens will cost you about $200.

Using click frames also reduces waste coming out of your screen printing shop. While aluminum is easy to recycle, using less is always the better option. Since you won’t have to replace the frames every time you need a new screen (unless the frame is broken), you’ll be using less and doing your part to create a more sustainable industry.

RELATED: HOW TO INSTALL MESH ON ECO FRAMES

MESH TENSION

Alright, now the question you’ve been waiting for: what is mesh tension and why does it matter? Mesh tension is essentially how tightly the mesh is stretched across a screen. 95% of printing issues directly relate to the tension of the mesh. Ultimately, screens with super low tension won’t pop off the garment like they’re supposed to.

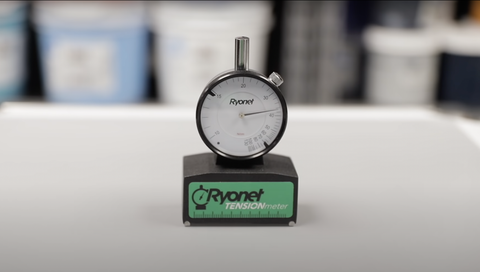

As we said before, a good rule of thumb for mesh tension is 25 newtons. Lower mesh counts can have higher tension since these screens are generally used for designs with less detail. If the print has high detail, you’ll need a higher-tension screen. A tension meter is a good tool to have on hand for shops wanting to have precise screen tension numbers. Overall, though, you’ll be able to estimate the tension of a screen based on how it performs on press.

RELATED: MESH COUNT AND YOU

Both static and click frame screens have their uses. But which is best for your shop?

WHICH SCREEN SHOULD YOU BUY?

If you’re starting up a shop, not printing a ton of detail or high-volume orders, the mesh tension of your screens isn’t too big a deal. Shops printing large spot color designs, block text, or small volume designs won’t have a problem buying static frames.

For shops printing a ton of detail or having orders of large volume, screen mesh tension will become a bit more noticeable. If you’re going through screens because they’re losing tension, it might be time to switch to click frames like Eco Frames.

CAN YOU RE-STRETCH SCREENS YOURSELF?

With all this talk of screens, you might be looking for an alternate route. Stretching your own screens is possible in two ways. The first is to purchase a roller frame and stretch screens that way. This is done by stretching the mesh in the roller screen to the tension you want, then gluing it to the frame. This requires some extra equipment, like a tension meter. This method is all about run time. Large automatic shops will benefit from stretching their own screens because they can reach higher tension and print more quicker.

The second method of stretching your own screens is to invest in stretching clamps. These aren’t cheap, and this method isn’t a viable option for many shops. Most of the time, this method creates the same quality screen that you could buy right off the shelf.

Overall, stretching your own screens can improve your print performance, but takes monetary investment, time, and lots of effort. Unless you’re replacing screens left and right because of tension issues, buying static or click-frame screens is the best option for many shops.

With different options for screen printing screens, there’s a lot to consider. Every shop has a preference, and switching from one type of screen to another requires a little bit of learning and experience. No matter what, do your research and make sure that the screens you’re using are increasing your print performance, not holding you back.