Printing multi-color designs is a skill all printers need. White single-color prints are a screen printer’s bread and butter. A multi-color design takes skill, tight registration, and a bit of patience. Generally, printers use presses with micro-registration to help them get the best registration possible without a headache. A press without micros can get the job done, too. Print enthusiast, Jamie wanted to push the limits of the Riley Hopkins 150 4x1 press with a 4-color blended design.

SETTING UP

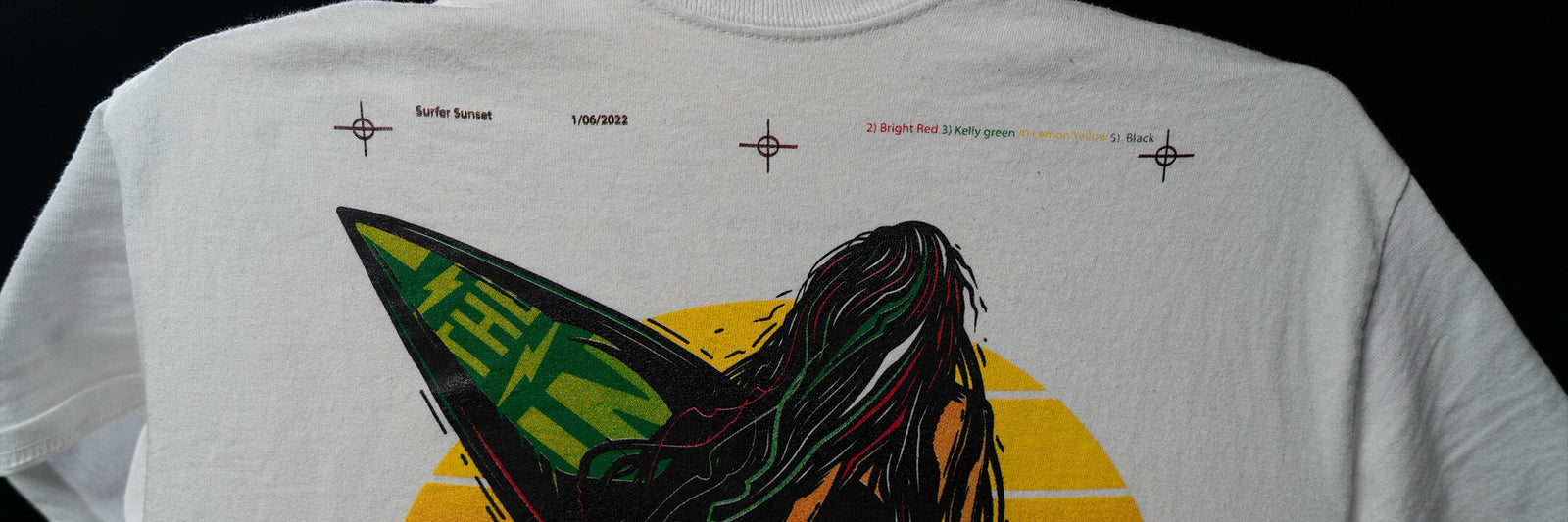

First up, the setup. A 4-color design requires 4 screens. The colors for this design are Kelly Green, Lemon Yellow, Bright Red, and Black. This print will max out the 4 colors on the 150 4x1 press.

When setting up a multi-color job, it’s important to place the films on each screen in the exact same place. If the films sit on different spots of their respective screens, registering the screens to a print can be nearly impossible, especially on a press without micros. Jamie used a registration template to register her screens, but the process can be done with a T-square as well. Check out the video below for a walkthrough:

Next up, it’s time to dial in off-contact. Off-contact is the space between the platen and the screen. Off-contact can be anywhere from 1/16” (one-sixteenth of an inch) to 1/8" (one-eighth of an inch). The goal is for the screen to snap off the print directly behind the squeegee as it travels across the print. To measure this, place a few cleanup cards on the corners of the platen and adjust the screen in the print head so that it sits evenly on the cleanup cards.

RELATED: HOW TO REGISTER A MULTICOLOR PRINT ON THE RILEY HOPKINS 150 PRESS

Once off-contact is uniform across all screens, it’s time to start registering.

REGISTERING THE PRINT

Micro-registration uses knobs to control the precise movement of the screen while it's in the screen clamp. This makes registering multi-color prints easy. The Riley Hopkins 150 press, however, does not have micro-registration. For designs without high detail or larger spot colors, this isn’t too big of an issue. Blockier designs will be far more forgiving if a print is a hair out of register. In an effort to push the limits of the press, Jamie’s design is a high-detail print meant to be registered with micros.

Without micros, Jamie must register each screen by loosening the clamp, tapping it into place, and then tightening the screen down again. This can be time-consuming and makes all that pre-registering prep more important.

First color up: black. Since it’s the screen with the most surface area on the shirt, Jamie centers it on the screen and prints it onto a test shirt. During production, the black outline would be printed last. But for registering, Jamie wants to be sure that all the colors are lined up to this outline.

Next, it’s time for the lemon-yellow screen. The registration isn’t too far off from where Jamie placed it initially. Before she prints, she covers the black outline on the t-shirt with tape. Using registration tape — or packing tape, like Jamie’s using — is a great way to register a print without creating multiple test shirts. By laying down tape, you can print directly onto the tape, check the registration, and then wipe the ink off the tape and move on to the next color. This hack reduces t-shirt waste and can speed up the process of registration.

Jamie gets the yellow screen as close to registration as possible, then moves on to the green.

THE IMPORTANCE OF REGISTRATION MARKS

When registering a print, pay close attention to the registration marks. These will be the best indication of whether the print is in registration or not. If you can see the black registration mark peeking out from behind the color you’re trying to register, it isn’t quite right.

Jamie added ink to the green screen before registering it to the black outline. This means she’ll only be able to see the top registration marks, rather than all the marks on the screen. She starts registering, hoping that her pre-registration prep has paid off. The bottom registration marks are spot on, but the top — the marks Jamie could see — are off. She wipes off the green ink from the tape and tries again.

Registering screens to a print without micros to help can be tricky. Thankfully, the last screen Jamie needs to register, the Bright Red, goes off without a hitch on the first try. After one hour and 15 minutes of screen registration, it’s time to do a test print.

RELATED: THE BEST WAY TO REGISTER WATER-BASED AND PLASTISOL SCREEN PRINTS

THE TEST PRINT

Now, the moment of truth. Jamie starts with the Lemon Yellow screen, printing the Kelly Green on top. The green screen is still a little off. Jamie doesn’t want to go back to the drawing board and re-register the green. Instead, she keeps the screen in the clamps, tapping it to help the screen move a tiny bit.

Now, the red screen. While it was perfect during registration, it shifted during test printing, too. Jamie taps the other side of the screen at the back to shift it back into registration. The black outline pulls the print together, trapping some of the ink that was out of register. While some elements are noticeable — like the green streak of hair on the surfer’s head — the overall print is very close to being in registration. One more test print should do it.

“As long as you’re willing to take the time and patience it takes to register the multi-color [print], you can do it,” Jamie said.

HOW CAN I MAKE THIS EASIER?

If you’re looking to make multi-color prints standard offerings in your shop, look at a press with micro-registration, like the Riley Hopkins 250. This press is equipped with XY micro-registration knobs. All that tapping that Jamie did can be done with a twist of a knob on the 250 press. With the option of 6 colors and 4 stations, printers can take their business to the next level, printing more colors and more shirts.

Want even more registration capability? The Riley Hopkins 300 features XY registration, plus another micro: the Z micro. A Z micro raises the off-contact of individual printheads. The Z micro helps a lot when you’re switching from different substrates in the same job.

Let’s say you have a job that calls for hoodies and T-shirts with the same design. With a Z micro, all you have to do is twist the knob to raise your screens to the height you’ll need. You won’t have to worry about re-registering every screen again. It’s all about efficiency and precision.

RELATED: WHAT’S THE DIFFERENCE BETWEEN THE RILEY HOPKINS 250 AND 300 PRESSES?

Registering multi-color prints on a press without micro-registration takes a little patience, but can be done. The print Jamie registered pushed the limits of the press: more forgiving multi-color designs will be much easier to register on a Riley Hopkins 150. For shops looking to make multi-color prints their go-to option, a press with micros will increase their shirts per minute and decrease registration time and stress.