Upgrade your printing process with the RevolvInk Mixer and the Wilflex Rio Mixing System. Save time and money with this efficient two-in-one plastisol line, perfect for screen printers on a budget. Easily create any Pantone Coated Color or use the pre-mixed colors for a hassle-free printing experience. Say goodbye to manual ink mixing and say hello to precision and speed.

WILFLEX™ Epic Rio Plastisol Ink Mixing System is a low cure non-phthalate finished ink mixing system formulated for a perfect balance of color accuracy and opacity for peak press performance and color design. It is an easy-to-use color mixing system with 18 inter-mixable colors, enabling printers to produce accurate PANTONE® simulations. EPIC RIO MIX is the most opaque color system in the line of Wilflex mixing color systems. Its opacity helps printers get to color quicker even when using fine mesh screens, saving ink and money.

Note: The mixing system software is only compatible with PC-based systems. For Mac and/or Smartphone users, please visit the mixing website (be aware that you will need to register and be approved before having access to the mixing system and compliance information).

REVOLVINK FEATURES

- Quickly modulates/warms all types of inks, including thick white inks

- Simple to blend custom ink colors

- Allows for quick and easy paddle replacement

- Mixes quarts and gallon containers

- One quart & one gallon paddle included

- Adjustable speed with the range of 0-40 RPM

- Lift and rolling action, causing no bubbles or ink splashes

- Small footprint

- 3-Point Locking Jaw System

- Powder-coated steel & zinc-plated construction

- Brushless, high-torque BLDC motor with an integrated axial fan

- Warranty

- Made in the USA 🇺🇸

WILFLEX EPIC RIO FEATURES

- Accurate and vibrant color match

- PANTONE® approved

- Excellent color reproduction over bases and white, light garments

- Matte finish

- Easy and accurate color mixing with finished inks that are balanced for viscosity

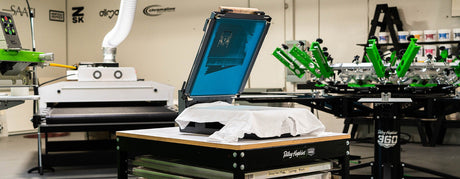

- Creamy inks that perform on both manual and automatic presses

- Best color fastness to crocking test

- Wet-on-wet printing capabilities at high production speeds with good resistance to build-up

- Consistent across short runs, long runs, color-to-color, and batch-to-batch

- Low cure properties (260°F–280°F)

- Soft-hand prints

QUART MIXING KIT INCLUDES

- 1 - Pantone Mixing Formula Guide

- 1 - Digital Lab Scale 500g x 0.01 g

- 10 - Empty Quart Containers w/lids

- 1 - Wilflex Rio Mixing White Gallon

- 1 - Wilflex Rio Mixing Deep Black Quart

- 1 - Wilflex Rio Mixing Blaze Orage Quart

- 1 - Wilflex Rio Mixing Red Quart

- 1 - Wilflex Rio Mixing Barberry Maroon Quart

- 1 - Wilflex Rio Mixing Majestic Magenta Quart

- 1 - Wilflex Rio Mixing Deep Violet Quart

- 1 - Wilflex Rio Mixing Midnight Blue Quart

- 1 - WIlflex Rio Mixing Aquamarine Quart

- 1 - Wilflex Rio Mixing Forest Green Quart

- 1 - Wilflex Rio Mixing Indigo Blue Quart

- 1 - Wilflex Rio Mixing Sunshine Yellow Quart

- 1 - Wilflex Rio Mixing Golden Yellow Quart

- 1 - Wilflex Rio Mixing Electric Yellow Quart

- 1 - Wilflex Rio Mixing Electric Red Quart

- 1 - Wilflex Rio Mixing Electric Pink Quart

- 1 - Wilflex Rio Mixing Electric Blue Quart

- 1 - Wilflex Rio Mixing Electric Purple Quart

GALLON MIXING KIT INCLUDES

- 1 - Pantone Mixing Formula Guide

- 1 - Digital Lab Scale 500g x 0.01 g

- 20 - Empty Quart Containers w/lids

- 1 - Wilflex Rio Mixing White 5 Gallon

- 1 - Wilflex Rio Mixing Deep Black Gallon

- 1 - Wilflex Rio Mixing Blaze Orage Gallon

- 1 - Wilflex Rio Mixing Red Gallon

- 1 - Wilflex Rio Mixing Barberry Maroon Gallon

- 1 - Wilflex Rio Mixing Majestic Magenta Gallon

- 1 - Wilflex Rio Mixing Deep Violet Gallon

- 1 - Wilflex Rio Mixing Midnight Blue Gallon

- 1 - WIlflex Rio Mixing Aquamarine Gallon

- 1 - Wilflex Rio Mixing Forest Green Gallon

- 1 - Wilflex Rio Mixing Indigo Blue Gallon

- 1 - Wilflex Rio Mixing Sunshine Yellow Gallon

- 1 - Wilflex Rio Mixing Golden Yellow Gallon

- 1 - Wilflex Rio Mixing Electric Yellow Gallon

- 1 - Wilflex Rio Mixing Electric Red Gallon

- 1 - Wilflex Rio Mixing Electric Pink Gallon

- 1 - Wilflex Rio Mixing Electric Blue Gallon

- 1 - Wilflex Rio Mixing Electric Purple Gallon

RECOMMENDATION FOR USE

For single print colors, colors will reproduce best over white or light-colored garments. When printing on a base white, some color shift may occur. This is normal and can be adjusted for by either printing a thicker ink deposit with lower mesh counts or by print-flash-print the color. You can also choose a slightly darker color in the PMS book. When it’s printed over the base white, it will typically lighten up and be a closer match. When direct printing over dark cotton, there is no guarantee you will maintain color integrity due to each ink's inherent opacity. As a result, not all colors will have good coverage when printed directly to fabric.

If printing a new PMS color, test through a 156 mesh onto white fabric, cure, and color checked in a light corrected box, or light correct space. Printing onto mid- or dark-colored garments may require the use of a base white for best color reproduction. Since all PMS colors (across all ink mixing systems) vary in opacity and coverage, it’s recommended to test before running production.

MIXING INSTRUCTIONS

- Open up the IMS software on your PC and log in. If using the mobile version, you must register and be approved before gaining access.

- Search for the PMS color you want to mix or use the drop-down menu to scroll and locate the color.

- Update the amount of ink you want to mix.

- The right side of the screen will show the PMS color and the mixing components.

NOTE: The Rio Mixing System is different from the RFU (Ready For Use) colors, and is formulated differently. Use only the mixing inks for creating custom colors.

Got your ink color? It’s time to start mixing:

- Place the container onto the scale and zero it out.

- Start adding the ink with the highest volume listed in the formula.

- Once the appropriate amount is in the container, clean off the spatula with an ink cleaner like Supreme Wash. You can also use a spatula for each color to avoid contaminating the inks.

- Place the ink container back on the scale, zero out the scale again, and add the next highest volume. Repeat as necessary.

- Once all the colors have been added to the container, use a clean spatula to mix the ink. Be sure to scrape the ink from the bottom of the cup and mix it into the rest of the ink.

CURING INSTRUCTIONS

Flash at 220°F (105°C) for 3 - 5 seconds. Adjust flash cure temperature and dwell time so the ink is just dry to the touch. Depending on the flash unit, a 2 - 3 second flash is adequate.

Rio inks will cure when the entire ink layer has reached at least 260°F throughout the entire ink layer. Rio inks are stable when cured at higher temperatures. Cure temps ranging from 260°F to 280°F are considered standard and the ink will remain stable as temperatures climb above 300°F-320°F. Rio can be used on the same design with standard cure (320°F) inks.

Curing is a time and temperature process. To protect the fabric, control dye migration, and reduce energy consumption, set the conveyor to a lower dryer temperature setting with a slower belt speed while maintaining the recommended ink cure temperature.

All plastisol ink should hold at cure temp or higher over time. Anywhere from 5 seconds to 10 seconds is optimal. This additional time at cure temperature increases an inks performance characteristics like stretch and abrasion resistance.

CLEAN UP

Ink degradent or press wash.

STORAGE INFORMATION

Store at 65-90°F (18-32°C), avoiding direct sunlight.