Your embroidery machine is a powerhouse, but even the best machines need a little TLC when a needle snaps or wears out. The good news? Changing a needle is quick and simple when you know the steps. Let’s get your machine running smoothly again.

WHY NEEDLE CHANGES KEEP YOUR MACHINE RUNNING SMOOTHLY

Your embroidery needles work hard, and a bent, dull, or broken one can cause thread breaks, skipped stitches, or even damage your material. On the ZSK Sprint Classic, needles often break when they hit the frame—usually because the design wasn’t properly mapped to the hoop. Save yourself some trouble by double-checking your design placement before starting any project.

If a needle does break, don’t worry. Here’s how to fix it fast!

RELATED: HOW EMBROIDERY CAN TAKE YOUR SCREEN PRINTING BUSINESS TO THE NEXT LEVEL

WHAT YOU NEED

To replace a needle, you’ll need:

- #4 Allen wrench (it comes with your machine).

- Replacement needle

Pro tip: Keep various needle sizes on hand for different projects. Thin needles work great for delicate fabrics, while heavier-duty needles are ideal for thick materials like denim or leather.

STEP-BY-STEP: HOW TO CHANGE A NEEDLE ON YOUR ZSK SPRINT CLASSIC

1. STOP, LOCATE, AND LOOSEN

The moment you hear a snap or see a bent needle, hit the emergency stop button. Grab your #4 Allen wrench and find the small black screw at the top of the needle bar.

Turn the screw slightly to the left (lefty loosey). Don’t unscrew it all the way—just enough to loosen the old needle.

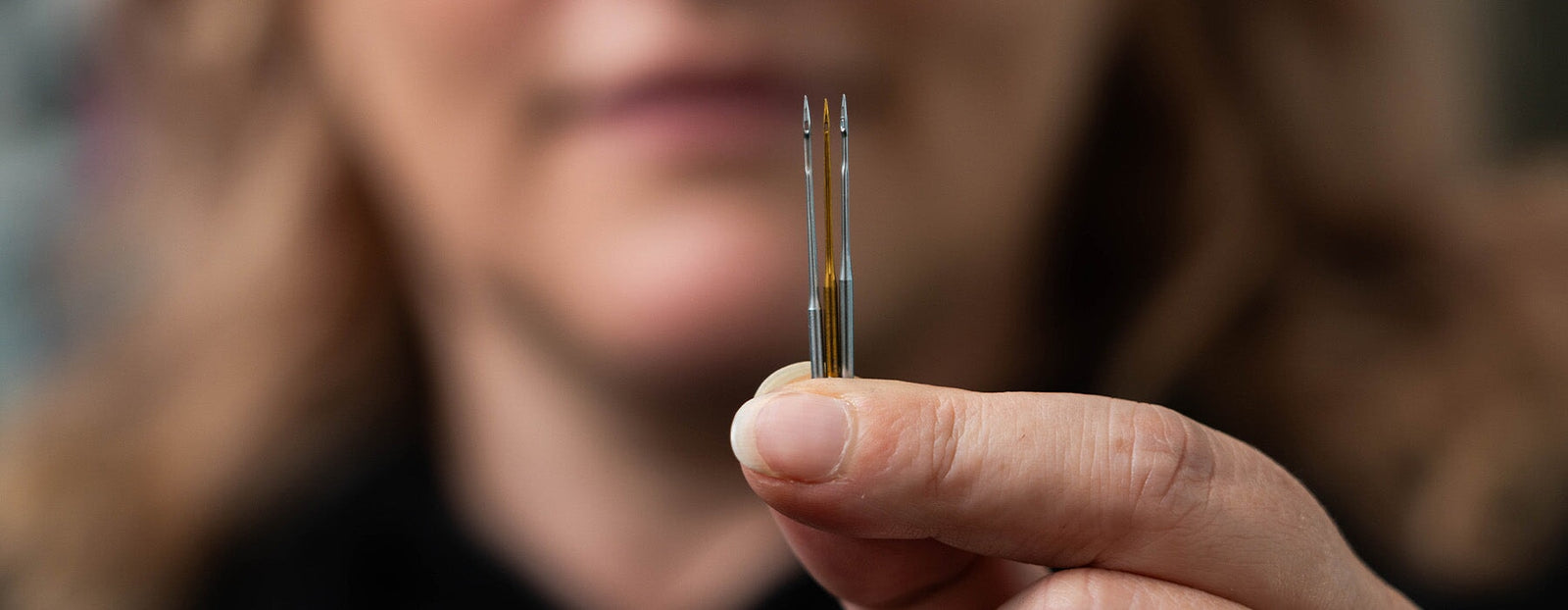

2. REMOVE AND ALIGN THE NEW NEEDLE

Slide out the damaged needle and grab your replacement. Check the needle’s alignment:

- The grooved side faces away from you (toward the thread path).

- The flat side faces forward (toward you).

Proper alignment is critical for smooth stitching.

RELATED: HOW TO CREATE STUNNING 3D PUFF EMBROIDERY

3. INSERT AND TIGHTEN

Insert the new needle into the holder, pushing it all the way up until it’s snug. Make sure it’s aligned with the other needles. Tighten the screw to the right (righty tighty) to secure the needle in place. Be careful not to overtighten—it just needs to stay steady.

4. THREAD AND TEST

Thread the new needle as usual. Turn the machine’s wheel manually to check the needle’s movement. It should move freely without hitting the presser foot or frame.

Before starting on your project, test the needle on scrap fabric. This confirms everything is set up correctly.

PICKING THE RIGHT NEEDLE FOR YOUR FABRIC

Using the right needle ensures clean stitches and prevents unnecessary wear on your machine. Here’s a quick guide:

| Needle Size | Material | Best For |

|---|---|---|

| 60/8 | Sheer fabrics, fine embroidery | Thin threads, small text, delicate designs |

| 70/10 or 75/11 | Standard cotton, polyester fabrics | Everyday designs on medium-weight fabrics |

| 80/12 to 120/19 | Denim, leather, canvas, heavy fabrics | Thick materials requiring durability |

PREVENT NEEDLE PROBLEMS BEFORE THEY HAPPEN

Take a few extra steps to keep your machine in top shape:

- Change needles regularly. A dull needle struggles to pierce fabric and can ruin your design.

- Check your hoop setup. Make sure your design fits the hoop to avoid needle collisions.

- Stock up on spares. Running out of needles mid-project is never fun.

KEEP YOUR MACHINE RUNNING LIKE A DREAM

With these steps, replacing a needle on your ZSK Sprint Classic is quick and hassle-free. Regular maintenance keeps your machine running at peak performance and ensures your projects always come out looking professional.