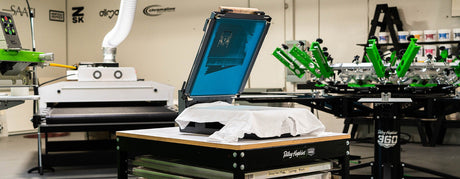

Take Your Creativity to the Next Level with Ryonet’s xTool Laser Xperience 🔥🛠️

You know Ryonet—we’re all about empowering makers and helping you turn your creative hustle into something real. So when we say our xTool Laser Xperience Workshop is a game-changer, we...